One of the main areas of growth for Spectrum Logic is the global automated X-ray inspection (AXI) market. AXI is a growing market driven by advances in semiconductor packaging, AI chips, electric vehicles and aerospace. Within AXI we have been focusing on inline electronics inspection.

What is inline electronics inspection?

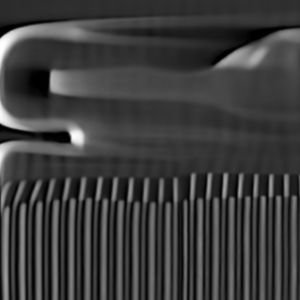

X-ray of a Printed Circuit Board (PCB)

Inline electronics inspection is a fully automated X-ray inspection (AXI) process, which uses 2D X-ray or 3D computed tomography (CT) to rapidly, non-destructively, inspect parts as they are being manufactured. It can be used to inspect:

- electronic components

- printed circuit boards (PCBs)

- EV battery cells

- power module units

- semiconductor components

Inspection is performed ‘inline’, which means it forms part of the production line and examines 100% of the goods manufactured. This means that the throughput of the production line is limited by the frequency with which the AXI system can inspect items. This in turn means that fast X-ray detectors are preferred because they allow a higher throughput. For example, electric vehicle battery cells are inspected with 3D X-ray CT at a rate of 20 to 30 parts per minute (PPM). These high throughput systems also require a powerful X-ray source.

X-ray of an EV battery cell

We are in the middle of an industry transition from inline quality inspection dominated by automated optical inspection (AOI) to one dominated by AXI. This is driven by increasing complexity of PCBs and semiconductor packaging in AI chips and other high-end hardware, with technologies such as multilayer ceramic capacitors (MLCC), high bandwidth memory (HBM), TSVs and micro-bumps requiring X-ray rather than optical inspection.

The leaders in AXI systems are located in Japan, Germany, Taiwan, Korea and China. Spectrum Logic is working with leading players in AXI in all of these countries.

What do Spectrum Logic offer for inline electronics inspection?

The main products we offer for inline electronics inspection are 3131HS, 2824HS, 2824HR, 2812HS, 2812HR, 1412HR 1206HR and 0606HR.

We are developing 1615HE with a 75 µm pixel pitch and a frame rate of 80 fps. The square active area of this detector is an advantage for inline electronics inspection as PCBs under inspection, can be rotated, to increase the speed. The 75µm offers the perfect balance between efficiency and resolution and will be a valuable addition to our product portfolio. Now Spectrum Logic has 50,75 and 100µm covering every industrial application.

Spectrum Logic HR (High Resolution) Family CMOS X-ray detectors suitable for inline electronics inspection

Spectrum Logic HS (High Sensitivity) Family CMOS X-ray detectors suitable for inline electronics inspection

“Inline electronics inspection is our focus right now because our detectors are well suited to this application because of their efficiency, speed and longer lifetime. By efficiency, I mean that we can get the same or better image quality at low dose than our competitors”

What makes Spectrum Logic Detectors ideal for inline electronics inspection?

Speed: high frame rates enable more parts per minute (PPM) to be inspected inline. In ROI mode, 2824HS can achieve 500fps in 28 x 5cm active area. This is comparable to photon counting detectors at a much lower price.

Lifetime: some inline systems run 24/7, so reliability and lifetime of the components in the system is vital. Ionizing radiation, like X-rays, can damage image sensors and other semiconductors, making X-ray detectors vulnerable to the very flux they are designed to measure. While detector electronics can be protected using materials like lead, the active imaging area cannot be shielded in the same way.

Spectrum Logic addresses this issue by incorporating special fiber optic faceplates (FOPs) between the scintillator and the CMOS image sensor. These FOPs block harmful X-rays while allowing the image produced by the scintillator's interaction with the X-ray beam to pass through. To further enhance durability, Spectrum Logic uses a specialized cerium-doped glass in its industrial FOPs to prevent X-ray-induced browning of the glass. By combining radiation-hardened CMOS image sensor technology with thick, radiation-tolerant FOPs, their detectors offer extended lifetimes and improved reliability.

Efficiency: CsI scintillators efficiently absorb a significant portion of incident X-rays, enabling them to produce high-quality images with excellent contrast, even at high frame rates and low power.

Why is low dose important in inline inspection?

Achieving high resolution in inline inspection requires the use of microfocus or mid-focus X-ray sources, which operate at low power. Low dose becomes important when aiming for faster inspections with these low-power sources, such as microfocus X-rays. While they provide high resolution, the dose is limited, making the efficiency of Spectrum Logic’s CMOS X-ray detectors crucial. As the power of the X-ray sources decreases, the performance of our detectors becomes a competitive advantage.

“There is always a trade-off between resolution and power: to achieve high resolution, you need to use lower power, so a detector with excellent dose efficiency is essential as flux decreases”

Inline inspection systems need to be fast, with real-time CT scans ideally completed in 2-3 seconds. A key metric in inline inspection is PPM, with industries continuously demanding faster processing times for components like batteries, chips, and PCBs. Battery CT system integrators, using our CMOS detectors, have been able to achieve inline 3D CT scans completed in just 3 seconds, enabling inspection of 20 ppm.

A further example of the efficiency of Spectrum Logic detectors is a customer who successfully reduced their inline PCB inspection time from 33-40 seconds to just 10-15 seconds using Spectrum Logic detectors.

X-ray of Ball Grid Arrays (BGA)

Spectrum Logic are working towards a complete solution for inline inspection for our customers

Inline inspection is a complex problem, which a detector manufacturer can not only approach in isolation. It is essential to work with X-ray sources to achieve optimal speed and image quality.

In order to offer a complete solution for our customers, Spectrum Logic are now collaborating with leading X-ray tube manufacturers to optimise how their X-ray sources and our detectors work together.

Spectrum Logic is collaborating with one leading X-ray tube manufacturer to develop a system for inspecting high bandwidth memory (HBM) and have been able to achieve images of 20 µm bump bond artifacts.

Spectrum Logic are working with another leading X-ray source manufacturer, who are targeting inline EV battery inspection with their latest high-power source (up to 225kV), which is popular with battery inspection system integrators.

By collaborating directly with the X-ray source manufacturers, we can achieve the fastest, high quality images. Together we can offer system integrators the optimal configurations for semiconductor, EV battery and electronics inspection.

What are our future plans / next steps?

We can see that AXI and battery inline inspection is a problem that has, to an extent, been solved and speed is what really makes Spectrum Logic detectors stand out in this market.

So, now we are looking at what other applications need solutions. We are working on advanced semiconductor packaging – for example, graphics processing units (GPUs) and multi-layer ceramic capacitor (MLCCs). MLCCs are a type of surface-mount ceramic capacitor that is used as a package for semiconductors.

MLCCs viewed under a microscope

Some of our customers are trying to come up with 100% inspection for advanced semiconductor packaging. The challenge they face is how to perform 100% inspection inline at speed. The semiconductor chips and the MLCCs are dense and tiny, which is very challenging, both in terms of a complex configuration of detectors/sources and also in terms of speed. It can take up to 10 minutes to CT these components. We have observed that there is a need for a very high resolution, very high efficiency detector which can offer much faster inspection and scans for the advanced packaged components for semiconductors.

For this we are developing the 6060XR (Extra Resolution) 10µm detector.

6060XR 10µm Scientific sCMOS detector

“The 6060XR will be a unique detector featuring a sensor designed specifically for real-time X-ray imaging with a small 10-micron pixel pitch and a choice of high-resolution gadox fibre optic scintillator or micro-columnar CsI. The monolythic, stitched 60 x 60 mm2 sensor will employ a novel ADC design and have an ultra low read noise of <10 electrons (compared to 100 electrons for a typical CMOS X-ray detector and over 1,000 electrons for TFT based detectors). The 6060XR will enable compact real-time inspection systems with very high spatial resolution without the use of high-ratio geometrical magnification, which causes problems when imaging small 3D structures. This novel detector will enable the development of new CT scanners for high-resolution CT imaging of advanced 3D semiconductor packing such as high-bandwidth memory (HBM), which is used in advanced AI chips. Advanced AI chips use stacked DRAM chips to achieve high-speed data transfer and low power consumption and new X-ray technology is required to image the tiny connections between these stacked chips.”