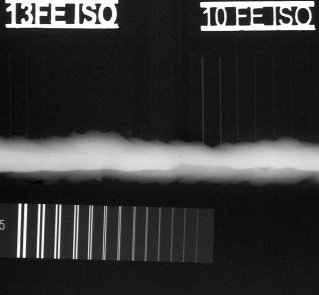

NDT: PIPE WELD INSPECTION

Pipe Weld X-ray

Pipe Weld Inspection plays a crucial role in preventative maintenance and asset protection within the world of Oil and Gas. NDT technicians, plant owners and pipe manufacturers use X-ray to find hidden flaws. They are checking for corrosion, erosion, weld quality, wall thickness and clogging. These inspection are vital to ensure the safety of facilities such as oil and gas pipelines, nuclear power stations and refineries. Portable digital radiography systems allow non-destructive testing of pipelines in the field and the factory. Spectrum Logic has developed radiation hardened, light weight, portable X-ray detectors with excellent image quality to assist with the inspection process. The HR family features a 50um pixel pitch and radiation hard FOP which is ideal for weld inspection because the FOP ensures a high level of radiation tolerance and the small pixel provides high spatial resolution.

RECOMMENDED DETECTORS (Click on image for data sheet):