Spectrum Logic 1615HS, 2121HS and 3131HS detectors are now available in lightweight versions that have been developed for surgical C-arm, mini C-arm and robotic surgerical imaging. These detectors can also be used in other applications where a lightweight and low-profile detector is desirable, such as robotic Computed Tomography (CT) X-ray for quality assurance and non-destructive testing. Spectrum Logic lightweight detectors are also used in backscatter mobile security X-ray.

Read MoreX-ray detector

Control 2024

Spectrum Logic at Control 2024

Spectrum Logic exhibited at Control 2024 - the international trade fair for quality assurance (23-26 April 2024) at Messe Stuttgart. We showcased our high resolution, high sensitivity CMOS X-ray detectors for non-destructive testing and quality assurance. Location: Hall 10 booth 1411.

CMOS Detectors for Pipe Weld Inspection

“Welding is a fabrication process whereby two or more parts are fused together by means of heat, pressure or both, forming a join as the parts cool” TWI Global

Welding plays a vital role in the oil and gas industry. Every part of oil and gas production process (Upstream, Midstream and Downstream) is dependent on robust, reliable welds. The industry has a wide range of welding requirements, from small diameter pipes to enormous rigs and platforms.

Definition of upstream, midstream and downstream segments in oil and gas industry

https://www.omsmeasure.com/guide-to-weld-inspection

Pipe Weld Inspection plays a crucial role in preventative maintenance and asset protection within the world of Oil and Gas. Non-destructive testing (NDT) technicians, plant owners and pipe manufacturers use X-ray to find hidden flaws. They are checking for:

· corrosion

· erosion

· weld quality

· wall thickness

· clogging

Digital X-ray detectors allow NDT of pipelines in the field and factory. Spectrum Logic has developed radiation hardened, light weight, X-ray detectors with excellent image quality to assist with the inspection process.

PIpe Weld X-ray

This pipe weld X-ray image was taken with the Spectrum Logic 1510HS detector.

This lightweight (0.8kg) CMOS X-ray detector was placed on a rotating gantry on the outside of a 36-inch OD steel pipe with a wall thickness of 0.666 inches. The X-ray source used an energy of 225kV.

1510HS CMOS X-ray Detector

The Spectrum Logic 1510HS detector has an industry leading thickness of 9mm, making it ideal for imaging hard to access objects, such as heat exchangers. It is a dynamic X-ray detector, with a pixel pitch of 100μm and a Gadox scintillator. It is ideal for portable applications and weld inspection. The USB 3 interface handles data output, control and power supply. A handle can be attached for manual operation. Automatic exposure control (AED) allows the detector to be used with a portable source without synchronisation.

Weld image taken using 1510HS (Courtesy of Visiconsult)

Other pipe weld images taken with our 1510HS CMOS X-ray Detectors:

Weld image taken using 1510HS (Courtesy of Visiconsult)

Another Spectrum Logic detector which is suitable for pipe weld inspection is 1412HR detector (with high resolution CsI Scintillator). The 1412HR was evaluated by Visiconsult X-ray Systems and Solutions.

Spectrum Logic 1412HR

The aim of the Visiconsult evaluation was to find out how the Spectrum Logic 1412HR detector measured up to the DIN EN ISO 17636-2 standard. This ISO (International Organization for Standardization) standard is for ‘non-destructive testing of welds — Radiographic testing — Part 2: X- and gamma-ray techniques with digital detectors’. The 1412HR detector is a dynamic X-ray detector suitable for pipe weld inspection, with a pixel pitch of 50μm and innovative sensor design which enables a frame rate of up to 29 fps and a programmable region of Interest (ROI) gives higher frame rates, for example with an ROI of 2804 × 1200 pixels can be read out at 58 frames per second. For the Visiconsult evaluation the detector was operated in its most sensitive mode and the aim was to discover how it achieved Class-B under challenging circumstances in a short space of time.

1412HR Evaluation Set up

Results:

· Due to the detector’s high resolution (50μm) there is a good contrast-to-noise ratio (SNR)

· Class A and B (according to ISO17636-2) can be achieved, without compensation, up to a wall thickness of 15mm.

(Test result image courtesy of Visiconsult)

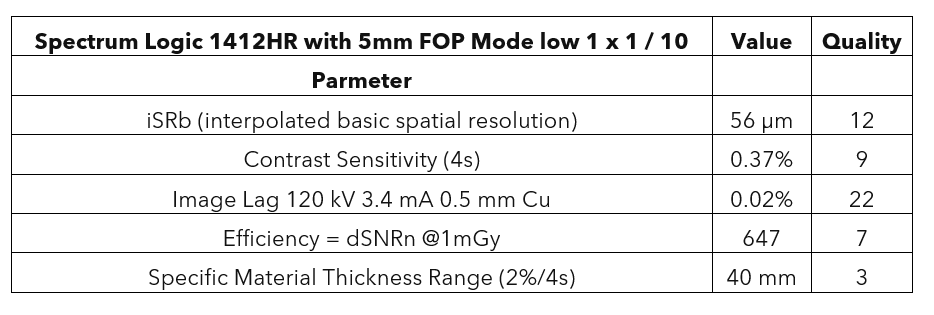

ASTM 2597 results using 1412HR 5 mm FOP

For this evaluation Customer 2 tested our 1412HR detector against the ASTM 2597 Standard Practice for Manufacturing Characterization of Digital Detector Arrays.

Results from repeated measurement with 5mm FOP and optimised gain setting.

These tests were conducted with >1sec exposure time due to acquisition constraints, some results are prone to high leakage. Better Signal to Noise Ratio (SNR) is achieved when exposure time is reduced to 500ms or less.

Conclusion

Spectrum Logic has developed radiation hardened, light weight, portable X-ray detectors with excellent image quality to assist with the pipe weld inspection process. Customer evaluations have shown that Spectrum Logic meet ISO and ASTM standards for use in the inspection process.

The HR family of detectors is particularly suitable as it features a 50um pixel pitch and radiation hard FOP which is ideal for weld inspection because the FOP ensures a high level of radiation tolerance and the small pixel provides high spatial resolution.

For more information contact us at inquiries@spectrumlogic.com or join us at ASNT 2023 (23-26 October) in Houston booth 316.

University College London paper proves edge illumination X-ray phase contrast imaging (XPCI) holds the potential to image soft tissue

X-ray phase contrast imaging (XPCI) is an exciting X-ray modality that can capture images that cannot be obtained with conventional radiography. The latter relies on absorption of X-ray photons whereas XPCI is based on a different physical principle: refraction. XPCI uses the phase shift experienced by an electromagnetic wave when it passes through a material. XPCI images provide higher contrast for features in low density materials such as human soft tissues, e.g., breast tissue, and composite materials such as carbon fibre-reinforced polymers. XPCI allows the detection and quantification of features of objects that are invisible in conventional radiography.

XPCI began with the extremely bright X-ray beams produced by large synchrotron radiation sources, such as those at the Diamond Light Source, the UK's national synchrotron science facility, located at the Harwell Science and Innovation Campus in Oxfordshire or the European Synchrotron Radiation Facility (ESRF) in France. Techniques were then developed to allow XPCI to be performed using conventional X-ray sources of the type used in medical and industrial radiography. One such technique is edge illumination XPCI. This achieves a relatively low dose exposure for the object and a relatively large field of view. It uses two masks that produce a structured X-ray beam by blocking part of the beam. The first mask is placed between the object and the X-ray source and the other is placed between the object and the detector and in contact with the detector.

A newly published paper in the Journal of Applied Physics ‘Replacing the detector mask with a structured scintillator in edge-illumination X-ray phase contrast imaging’ presents a proof-of-concept Edge Illumination XPCI system in which the second mask that is normally external to the detector has been replaced by a specially designed indirect conversion X-ray detector with sensitive and insensitive regions obtained by using a custom structured scintillator attached to a fibre optic faceplate. The project was led by Professor Alessandro Olivo from the Department of Medical Physics and Biomedical Engineering at University College London. Ed Bullard of Spectrum Logic was an author on the paper. The proof-of-concept detector was built by filling the apertures of a free-standing grid with fine P43 phosphor (terbium doped Gadolinium oxysulfide Gd2O2S:Tb). The period and aperture of the grid matched those of the detector mask normally used in Edge Illumination XPCI.

The paper presents images acquired with the original edge illumination technique using two masks and images of the same objects taken using the proof-of-concept edge illumination XPCI system. The novel system successfully allowed the visualization of features such as cartilage. Cartilage cannot be imaged using conventional absorption-based radiography and is normally imaged using expensive MRI systems.

The paper shows that edge illumination XPCI using a structured scintillator integrated into a high-resolution X-ray detector holds the potential to image soft tissue. It may even be possible to retrofit conventional X-ray systems for edge illumination XPCI.

For more information about XPCI contact the team at Spectrum Logic

For an overview of XPCI watch this UCL Lunchtime lecture by Prof. Alessandro Olivo: